Date of publication:2019-09-14 11:15:54 Article editor: Views:

In modern life, automobile is indispensable, which provides great convenience for people to travel. The industry chain of automobile industry is becoming more and more mature, and a series of automobile related industries derived from it have also been greatly developed. The field of automobile interior and exterior decoration has been very active in recent years, and the application of many new materials and technologies has brought new vitality to the field of automobile interior and exterior decoration.

Main points of automobile exterior design

If the car interior is to provide people with a comfortable driving experience, then the car exterior is to make the car more beautiful while ensuring driving safety. Because of the special functions of automobiles, automotive exterior accessories must adhere to the "three modernizations" design principle, that is, standardization, serialization and generalization. At the same time, they should also meet the "six requirements" of rationality, reliability, economy, advancement, maintenance convenience and manufacturing technology.

According to the different countries and regions where vehicle models are put into operation, the design process must fully implement the local laws and regulations. Mainly includes the specification of the distance between the front and rear bumper license plate installation holes, whether it is necessary to reserve fog lamp installation holes, lamp installation, external projection requirements and opening size, and whether the windward area of the radiator mask meets the requirements of engine, air conditioning and refrigeration, also needs the approval of relevant departments.

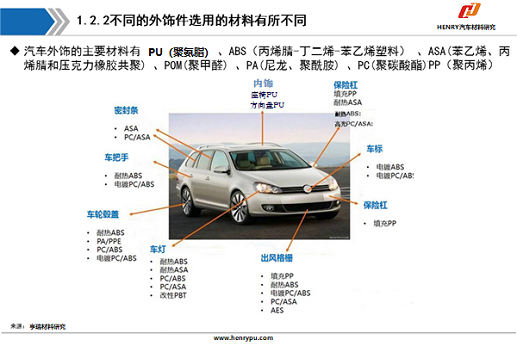

In addition, in several parts of automobile exterior decoration, the requirements for materials are also different. For example, the components of body parts such as rearview mirror, grille, fog lampshade and so on, need to have good heat resistance, scratch resistance, light resistance, chemical corrosion resistance, etc. Luggage rack, parking space, welding strip and other perennial direct sunshine parts need to have good heat resistance, low temperature resistance, light resistance, chemical corrosion resistance; Bars and other chassis near the need for good rigidity, scratch resistance, low-temperature impact resistance, impact resistance to gravel and so on.

Plastic Types and Automobile Exterior Decoration

At present, the plastics used in automobiles are generally PP (polypropylene), PE (polyethylene), PU (polyurethane), PMMA (polyether ether ketone), PA (nylon), PC (polycarbonate), etc. With the enhancement of environmental awareness and the exploration of new materials by scientific researchers, the emergence and use of new plastics have gradually expanded to the field of automotive exterior decoration. Cellulose extracted from straw, flax, beet, cottonseed hull and other plants can be made into bio-based plastics and applied in automotive field.

Although the strength of bio-based plastics is still a factor restricting its wide use in some special parts, there have been successful cases in the field of automotive exterior decoration. Previously, the material was used in the "bio-based" light electric vehicles built in the Netherlands. Not only does the strength-weight ratio of the relevant components approach that of glass fiber, but also the weight of the vehicle is greatly reduced.

Application of Plastics in Automotive Exterior Decoration

Compared with the metal materials used in the traditional automobile manufacturing, the plastic parts have lower cost and lighter weight, which conform to the trend of automobile lightweight. Therefore, more and more plastic automobile parts have replaced metal. Common automotive exterior accessories are front and rear bumpers, rearview mirrors, luggage racks, grilles, hub, lamp and its components, door handle components, radiator decorative cover, anti-collision beam, anti-scratch bar, wiper and so on.

We give examples of several common plastics used in automotive exterior decoration::

1. Bumpers: including front bumpers and rear bumpers. The bumper can absorb the energy generated when the vehicle collides, and reduce the damage to the body parts and passengers. It is necessary to have good impact resistance, weatherability, paint adhesion and other properties. Polyester, polypropylene and TPO are common in plastic bumpers.

2. Rearview mirror: Because of its long-term exposure to sunshine, rain and other climatic factors as well as driving turbulence and other factors, rearview mirror materials need to have a certain degree of weatherability. Considering the requirements of temperature, humidity, strength, impact and bending properties, the materials are not easy to ageing, corrosion resistance, good injection plasticity and spraying performance, etc. In general, heat-resistant ABS, PC, ASA, PBT + GF can be used as materials.

3. Luggage rack: Ensure that the rack is not damaged under various complex stress conditions. Require that the material has enough fatigue strength to ensure that the rack does not suffer serious fatigue damage when the car is running fast and braking emergency. Generally, PC/PBT, PC/ASA, PC/ABS, ASA and other materials can be used.

4. Vehicle lamp: It can be divided into headlamp, rear lamp, steering lamp, license plate lamp and so on. It plays an important role in the process of safe driving of vehicles. The combined headlamp is in the front of the whole car, it mainly plays the role of lighting and signal. Manufacturing lamp materials need to have good impact resistance, light transmittance, weather resistance, easy processing and other properties. Lampshades generally use PC or PMMA materials, lampshades generally use ABS materials.

In addition, it is noteworthy that with the increasingly obvious advantages of plastics, there is a trend to expand the use of plastic materials in covering parts and chassis accessories such as engine caps, tail doors, fuel tanks, etc.

For example, after 2000, the market share of plastic fuel tanks in the United States, the European Union and Japan has exceeded 90%, while the domestic market share is much lower due to lack of knowledge. However, according to the published "Standards for the Use of Vehicle Fuel Tanks" (GB18296-2001), both metal and engineering plastic tanks can enter the market as long as they meet international standards, which shows that plastic fuel tanks have been recognized by the state at the technical level, and the application scope of plastics in automobiles has been further expanded.

Conclusion: With the development of automobile lightweight, plastic is widely used in automobile decoration. Although there is still a long way to go for the application of plastics in automobile exterior decoration, with the support of science and technology, we have reason to believe that this field will usher in a new development climax.

date:09-10-2018 Views:52

date:11-11-2018 Views:63

date:27-03-2019 Views:100

TOP